How to Choose the Right Brake Pads for Your Fleet

Selecting the right brake pads for your commercial fleet is crucial for safety, performance, and cost-effectiveness. The wrong choice can lead to increased maintenance costs, reduced safety, and unexpected downtime.

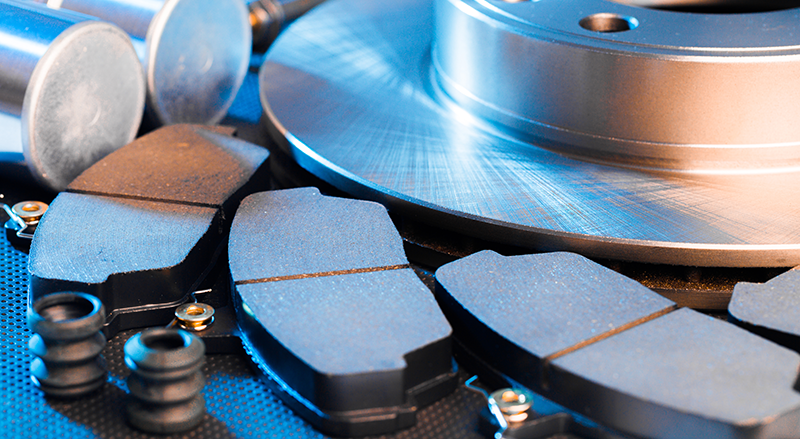

Understanding Brake Pad Materials

There are three main types of brake pad materials, each with distinct advantages and applications.

Organic Brake Pads

Made from organic materials like rubber, glass, and Kevlar fibers. These pads are quieter and produce less dust but wear faster under heavy use. Best suited for light-duty applications and city driving.

Semi-Metallic Brake Pads

Contain 30-65% metal content including steel wool, iron powder, and copper fibers. They offer excellent heat dissipation and durability, making them ideal for heavy-duty commercial vehicles and highway driving.

Ceramic Brake Pads

Made from ceramic fibers and non-ferrous materials. They provide consistent performance, low noise, and minimal dust production. Premium option for high-performance applications.

Factors to Consider

Vehicle Weight and Load

Heavier vehicles require brake pads with higher friction coefficients and better heat dissipation. Consider your typical payload and gross vehicle weight when selecting pads.

Operating Environment

City driving with frequent stops requires different pads than highway driving. Consider factors like stop frequency, weather conditions, road grades, and temperature extremes.

Cost vs. Performance

While premium pads cost more upfront, they often provide better value through longer life, reduced maintenance, and improved safety. Calculate total cost of ownership including initial pad cost, labor for replacement, rotor wear, and downtime costs.

Fleet-Specific Recommendations

Long-Haul Trucking

Semi-metallic pads are typically best for long-haul operations due to their durability and heat resistance. Look for pads with high temperature ratings and consistent friction characteristics.

Delivery and Urban Fleets

Organic or low-metallic pads may be suitable for frequent stop-and-go driving. Prioritize smooth engagement and low noise levels for urban environments.

Construction and Heavy Equipment

Heavy-duty semi-metallic or ceramic pads are essential for construction vehicles operating in harsh conditions with heavy loads.

Maintenance Best Practices

Regardless of pad type, proper maintenance is crucial. Regular brake inspections every 10,000-15,000 miles, monitor pad thickness and replace at 3-4mm, check rotor condition, maintain proper brake fluid levels, and train drivers on proper braking techniques.

Quality Standards and Certifications

Always choose brake pads that meet or exceed industry standards including FMVSS 121, SAE J2430, and Original Equipment Manufacturer specifications.

Investing in quality brake pads from reputable manufacturers ensures consistent performance, safety, and long-term cost savings for your fleet operations.